Product Features 111 Product Features 111 Product Features 111 Product Features 111

Flat idlers are vital components of belt conveyors, numerous in quantity. They account for 35% of a conveyor's total cost and bear over 70% of its resistance, making their quality crucial. Their function is to support the belt and material weight.

Idlers must rotate flexibly and reliably to minimize friction with the belt, significantly impacting the lifespan of the belt, which constitutes over 25% of the conveyor's total cost. Though small and structurally simple, producing high-quality idlers is challenging.

Application Range

1) Upper Flat Idlers / Lower Flat Idlers: Used in ports, docks, mining conveying, mechanical equipment.

2) Upper Flat Self-Aligning Idlers / Lower Flat Self-Aligning Idlers: Used to prevent belt misalignment.

Features

High wear resistance, very low friction coefficient, minimizes belt wear;

Excellent self-lubrication, no need for greasing, resists jamming in harsh conditions;

Anti-static, flame-retardant, weather-resistant, resistant to acid, alkali, and organic solvents;

Withstands repeated impact and vibration;

Operating Temp Range: -40°C to 90°C;

Excellent mechanical properties, lightweight, easy installation, maintenance-free;

Smooth operation, long service life.

Materials & Manufacturing

1) Shell: High-precision idler-specific steel tube, wall thickness ≥4.5mm. CO2 shielded welding ensures high-quality, precise welds.

2) Bearings: HRB, ZWZ, LYC bearings.

3) Bearing Housings: Stamped, internal welded structure.

4) Sealing: Triple sealing (outer seal, labyrinth seal, lithium grease seal).

5) Axial Play: ±0.5mm.

6) Dustproof: Complies with MT821-1999.

7) Waterproof: Complies with MT821-1999.

8) Bearing Overload Capacity: 170%.

9) Service Life: >50,000 hours.

10) Automatic welding for bearing housings using 4mm stamped steel plates.

11) Upper idler rotational resistance ≤0.020, lower idler ≤0.016.

12) Surface: Electrostatic spray painting (black anti-rust paint over primer).

13) Lubrication: Pre-filled with lithium-based grease.

14) High assembly precision ensures flexible rotation and maintenance-free operation.

Factors Affecting Idler Quality

1. Radial Runout (affects conveying stability)

2. Axial Play (affects service life)

3. Flexibility (affects idler & belt life, drive power)

4. Waterproof Performance (affects service life)

5. Dustproof Performance (affects service life)

6. Axial Load Capacity (affects service life)

7. Impact Resistance (affects service life)

8. Rotational Resistance (affects belt life)

Operation & Use

1. Inspect for damage before use; idlers should rotate freely without jamming.

2. Install spacing calculated based on material type, conveyor characteristics, and capacity.

3. Install to avoid mutual contact/friction.

Standard Idler Dimensions vs. Belt Width

Belt Width B Idler Diameter d Idler Length l

500 63.5, 76, 89 200, 315, 600

650 76, 89, 108 250, 380, 750

800 89, 108, 133, 159 315, 465, 950

1000 108, 133, 159, 194 380, 600, 1150

1200 465, 700, 1400

1400 530, 800, 1600

1600 133, 159, 194, 219 600, 900, 1800

1800 670, 1000, 2000

2000 750, 1100, 2200

2200 800, 1250, 2500

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questionsFrequently asked questions

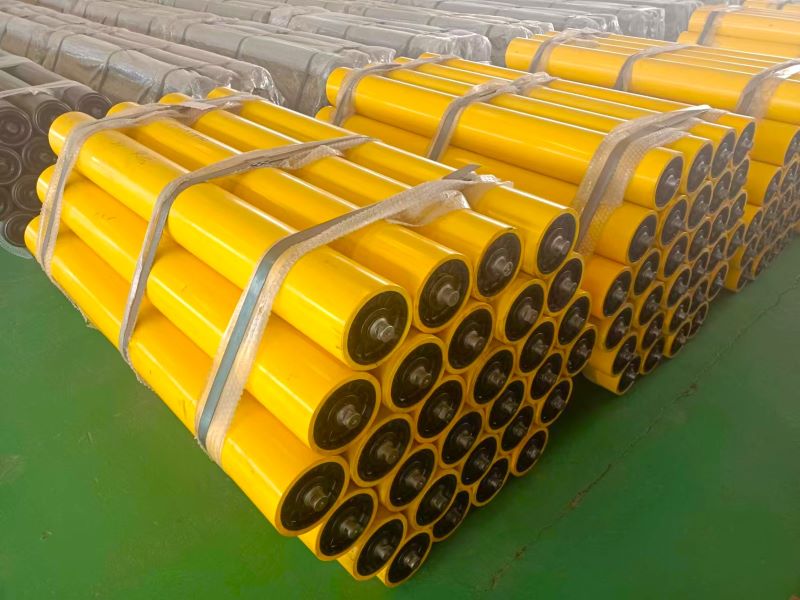

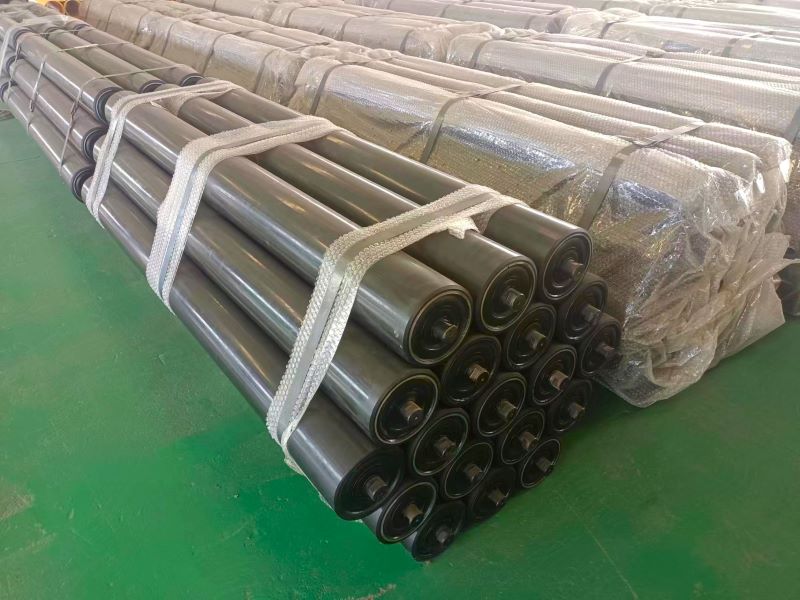

Frequently asked questionsPackaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

WeChat QR code

Scan it, you can chat on WeChat