Skeleton Ceramic Lagging Skeleton Rubber Lagging Skeleton Polyurethane Lagging Pulley Lagging Without Adhesive Pulley Lagging That Won't Delaminate or Shell Pulley Lagging That Doesn't Require Professionals Quick-Change Lagging Surface for Pulleys

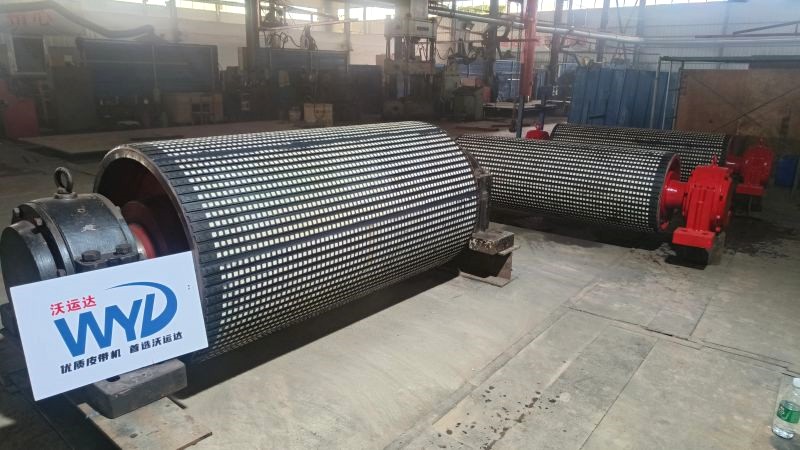

Skeleton Embedded Pulley Lagging

Skeleton embedded pulley lagging is a novel, durable covering method developed to address common issues with conventional lagging. This lagging requires no vulcanization or adhesive, reliably adheres to the pulley surface, allows quick replacement of damaged lagging surfaces, and prevents problems like debonding, shelling, or large-scale detachment.

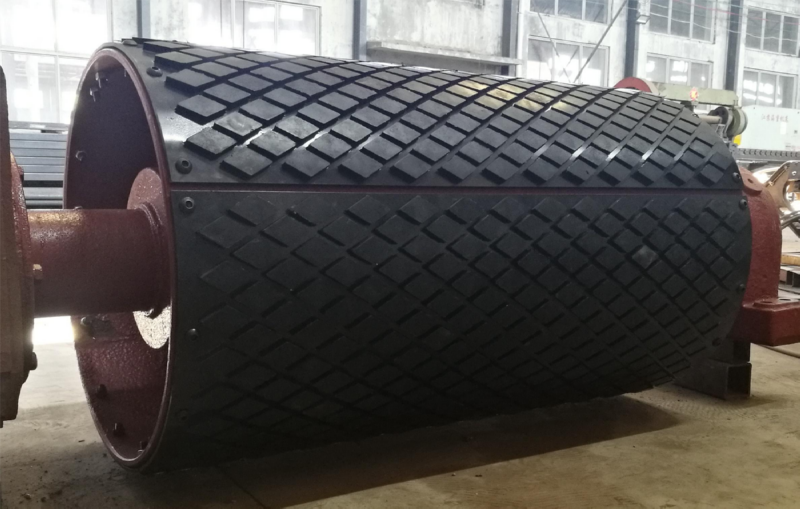

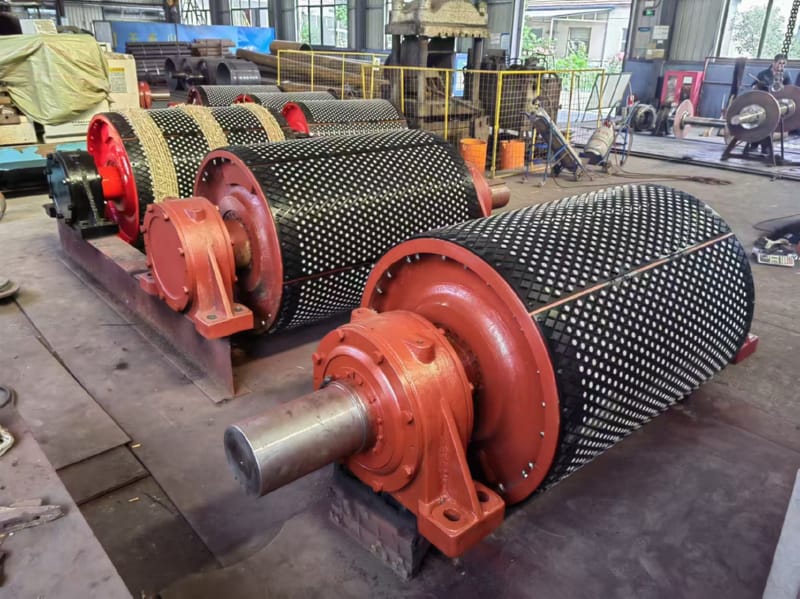

Skeleton embedded pulley lagging uses arc-shaped perforated plates as the skeleton. Wear-resistant rubber blocks are embedded into these plates to form anti-slip wear-resistant components. These components are fixed onto the pulley using the pulley's outer circumference as the base surface. The rubber wear blocks, diamond-shaped protrusions, are uniformly distributed on the pulley surface to form the lagging. During belt conveyor operation, the tension force applied to the lagging surface is transmitted through the rubber blocks to the pulley.

Multiple sets of anti-slip wear-resistant components are bolted onto the pulley, enabling simple and fast installation. Replacing the lagging surface again only requires bolting/unbolting for quick overall replacement. For localized damage, lagging surface maintenance is achieved by replacing individual rubber wear blocks.

Combining different materials for wear blocks and arc plates creates different lagging types: Skeleton Ceramic Lagging, Skeleton Rubber Lagging, and Skeleton Polyurethane Lagging.

Features:

■ The assembled anti-slip wear-resistant components are bolted onto the pulley. No vulcanization or adhesive is needed, eliminating issues like poor adhesion, debonding, or shelling. ■ Quick lagging surface change without pulley disassembly. ■ Uniformly spaced diamond-shaped protrusion pattern enhances mud and water drainage, improves pulley traction, allows operation in harsh environments, and prevents belt slippage. ■ Rubber and polyurethane blocks are molded under high pressure, resulting in high density and wear resistance superior to cold-bonded sheets and hot-vulcanized lagging. ■ In ceramic lagging using this technology, ceramic blocks are embedded in rubber, preventing detachment or chipping. ■ Pulley lagging no longer requires specialized equipment or personnel. ■ Long service life reduces maintenance and repetitive lagging hassles.

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questionsFrequently asked questions

Frequently asked questionsPackaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

WeChat QR code

Scan it, you can chat on WeChat