Product Features 111 Product Features 111 Product Features 111 Product Features 111

Overview

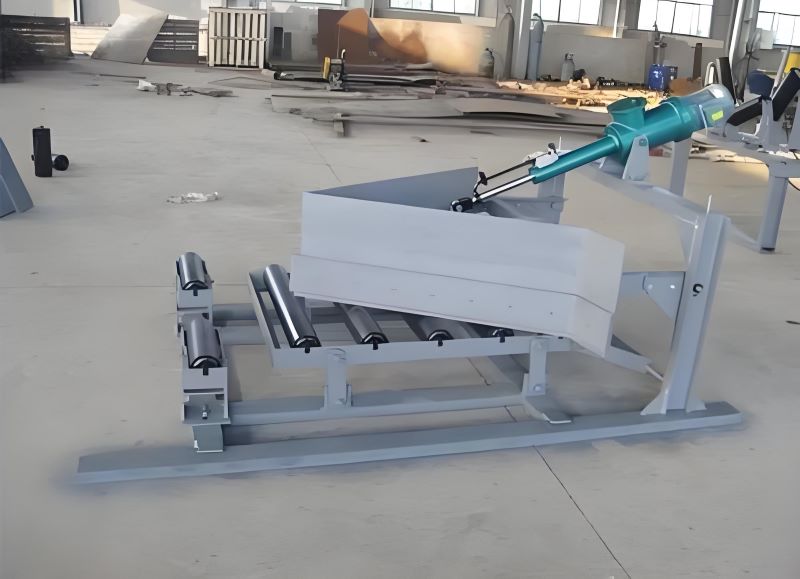

DYTN type electro-hydraulic plow type unloader is a mechanical supporting product installed on belt conveyors to perform unloading and control the flow and direction of material conveying. It can be directly installed on the intermediate frame of the belt conveyor, uniformly and continuously unloading materials transported by the belt midway into a hopper (material chute) or to the required location.

This product further improves the shortcomings of the original ZNX type unloader. By adopting a double plow head, plow head locking device, and a new type of electric hydraulic pusher, it overcomes issues such as incomplete unloading, belt scraping, poor overload capacity of electric pushers, frequent motor burnout, bent screw rods, and mechanical damage. It is currently one of the most advanced unloaders domestically. Reasonably designed, easy to operate and maintain, it can be controlled locally or remotely, widely used in power, metallurgy, coal, chemical, building materials, ports, and terminals.

Working Principle

The electro-hydraulic plow type unloader uses an electric hydraulic pusher as the power source. During operation, the pusher extends to act on the drive rod, driving the frame forward, completing the lowering of the plow knife, and supporting the flat idler group. This flattens the belt working surface, ensuring the lower edge of the plow knife fits tightly against the belt surface, unloading materials into the hopper or designated location. After unloading, the pusher retracts to act on the drive rod, driving the frame backward. The plow knife lifts, and the variable trough angle idler group changes from flat back to trough shape, restoring the belt working surface to its trough state for smooth material passage.

The electric hydraulic pusher adopts hydraulic transmission with automatic overload protection. When movement is obstructed, the oil pressure increases to the set limit, and the overflow device quickly and accurately relieves pressure, implementing overload protection. The motor operates within its rated value and will not burn out.

The hydraulic circuit integrated block of the electro-hydraulic pusher is designed with a self-locking mechanism. When power is cut off, the piston rod locks in position, maintaining pressure(For detailed electro-hydraulic pusher performance, please refer to the manual).

Structural Features

1、The electro-hydraulic pusher integrates mechanical, electrical, and hydraulic systems. It responds sensitively, runs smoothly, has accurate stroke control, and its working oil circuit circulates within pressurized sealed copper pipes. In harsh environments, it does not absorb dust, water, or leak oil, offering a longer lifespan than cylinders or electric pushers.

2、Designed in various sizes for different industries and sites, its installation dimensions can directly replace cylinders and electric pushers.

3、Adopts a variable trough angle idler group that automatically changes between flat and trough states according to working conditions, effectively preventing material spillage.

5、Features the latest plow head locking device. During operation, the plow knife will not lift or shake due to material impact. Its lower edge fits tightly against the belt surface with no material leakage.

6、Easy to operate and maintain, supports local or remote centralized control.

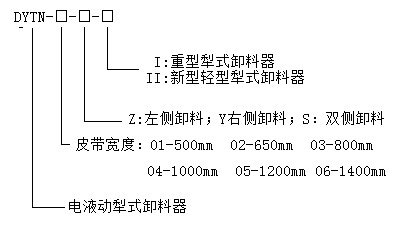

Model Numbering Explanation

Model Specifications

Suitable Belt Width | Unloading Type | Application Scope | ||

1 | B=500 | DYT700-200 | Left, Right or Bilateral | Bulk density ≤3.6t/m³ ores, coal, slag, chemical products, and other bulk materials |

2 | B=650 | DYT700-200 | ||

3 | B=800 | DYT1000-200 | ||

4 | B=1000 | DYT1000-300 | ||

5 | B=1200 | DYT1750-300 | ||

6 | B=1400 | DYT2500-300 | ||

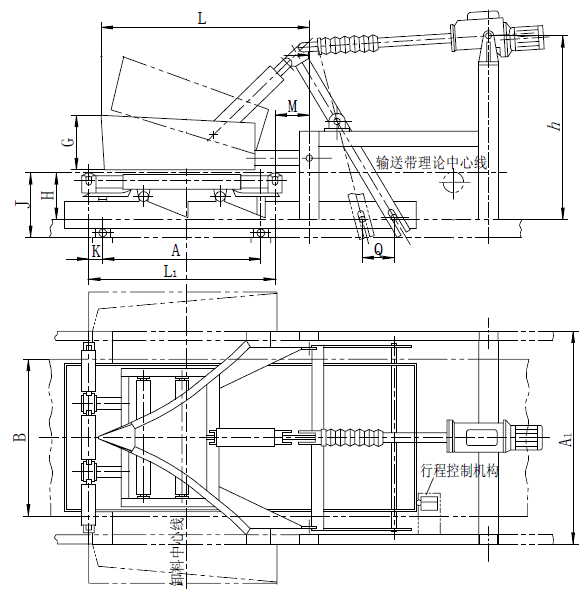

DTYN-S-I Heavy Duty Bilateral Plow Type UnloaderBilateral Plow Type Unloader Outline and Installation Dimensions:

Model | B | A | A1 | G | H | h | J | K | L | L1 | M | Q |

DYTN01Z(Y)I | 500 | 660 | 800 | 200 | 220 | 1130 | 320 | 120 | 910 | 900 | 200 | 125 |

DYTN02Z(Y)I | 650 | 880 | 950 | 250 | 235 | 1145 | 335 | 160 | 1010 | 1200 | 200 | 170 |

DYTN03Z(Y)I | 800 | 990 | 1150 | 300 | 270 | 1200 | 370 | 105 | 1075 | 1200 | 200 | 215 |

DYTN04Z(Y)I | 1000 | 1040 | 1350 | 350 | 300 | 1280 | 420 | 80 | 1335 | 1200 | 200 | 250 |

DYTN05Z(Y)I | 1200 | 1300 | 1600 | 400 | 335 | 1585 | 455 | 100 | 1510 | 1500 | 200 | 325 |

DYTN06Z(Y)I | 1400 | 1300 | 1810 | 450 | 350 | 1600 | 490 | 100 | 1710 | 1500 | 200 | 385 |

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questionsFrequently asked questions

Frequently asked questionsPackaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

WeChat QR code

Scan it, you can chat on WeChat