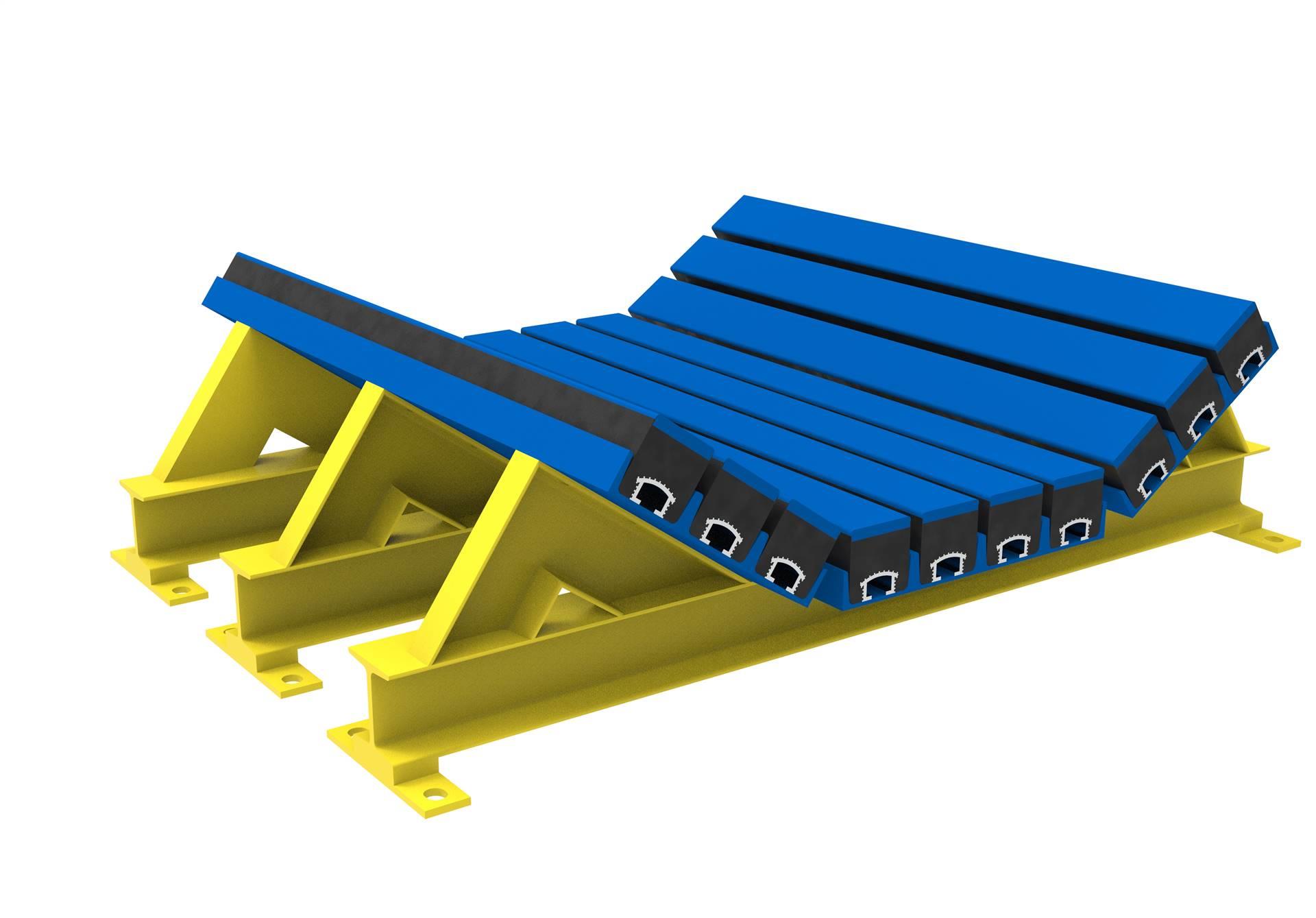

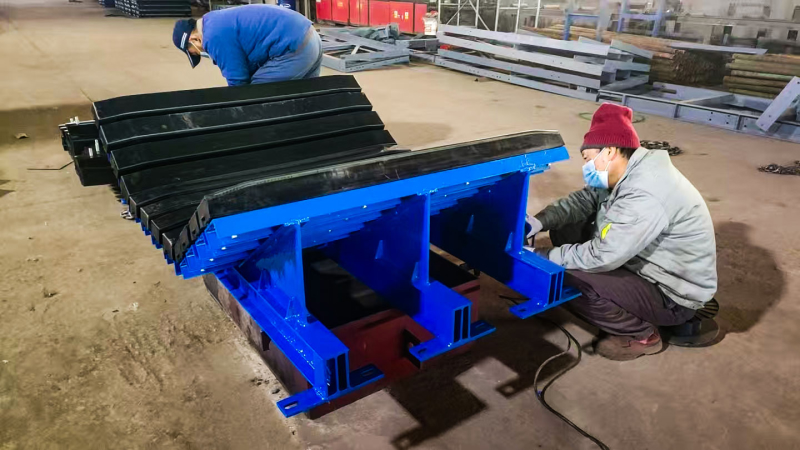

Heavy-Duty Buffer Bed Overview

Designed for high-drop transfer points and large-sized materials in conveying systems. High-density rubber buffer strips absorb impact forces from falling materials. Low-friction contact surfaces minimize belt abrasion. Detachable side sections and adjustable angles simplify maintenance, reducing labor/costs. Double-layer rubber skirts prevent dust spillage.

Technical Parameters

Belt Width: B=650~2400mm

Belt Speed: v≥4.5m/s

Capacity: Q≥6000t/h

Material Drop Height: h≥3m

Operating Temp: -20°C~90°C

Product Advantages

As specialized mining equipment, heavy-duty buffer beds offer impact/crush resistance, flame retardancy, anti-static properties, and corrosion resistance - ideal replacements for traditional buffer rollers. Surface-to-surface contact with belts prevents material damage.

Customizable for belt widths B650-B2400. Buffer strip lengths: 1220/1400/1600/1800mm. Bed angles: 35°-45° (fixed or adjustable).

High-elasticity rubber (hardness ≤55°) absorbs massive impact forces, improving loading point stress distribution. UHMW-PE surfaces (12.5/25mm thick) suit various belt speeds.

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questionsFrequently asked questions

Frequently asked questionsPackaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

WeChat QR code

Scan it, you can chat on WeChat