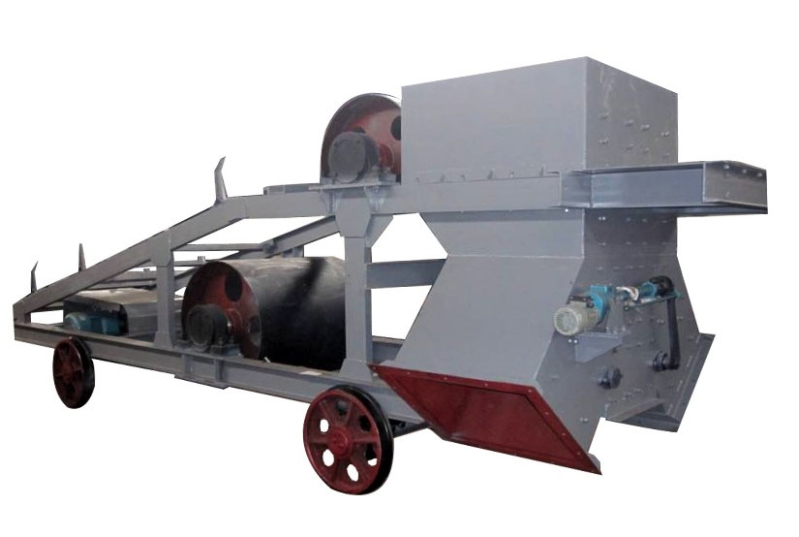

Tripper

Used for discharge at any point on horizontal conveyor sections. Types: Light-duty and Heavy-duty (single-side or double-side discharge). Max belt speed ≤2.5m/s.

Light-duty: For bulk density <1600kg/m³. Equipped with two-way chute (simultaneous discharge only). Belt width 500~1400mm. Custom designs (three-way chute/single-side discharge) available.

Heavy-duty: For bulk density ≥1600kg/m³. Double-side type discharges simultaneously. Single-side type (left/right) has 60° chute angle, designed for sticky powders (e.g., ore fines). Belt width 800~1400mm.

All types can add chute sealing devices. Intermediate frames/legs specially designed for strength/stiffness.

I. Purpose & Features

Discharges material at any midpoint, maximizing stacking/distribution area. Compact, reliable, long-life, easy maintenance. Used in mining, power, metallurgy, coal, ports, building materials.

II. Working Principle

Motor drives travel wheels via reducer/chain, moving tripper along rails. Material falls into discharge chute at tripper position.

III. Structure

Comprises frame, pulley set, idler set, drive unit, travel wheel set, chute.

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questions

Frequently asked questionsFrequently asked questions

Frequently asked questionsPackaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

Packaging and transportation

WeChat QR code

Scan it, you can chat on WeChat